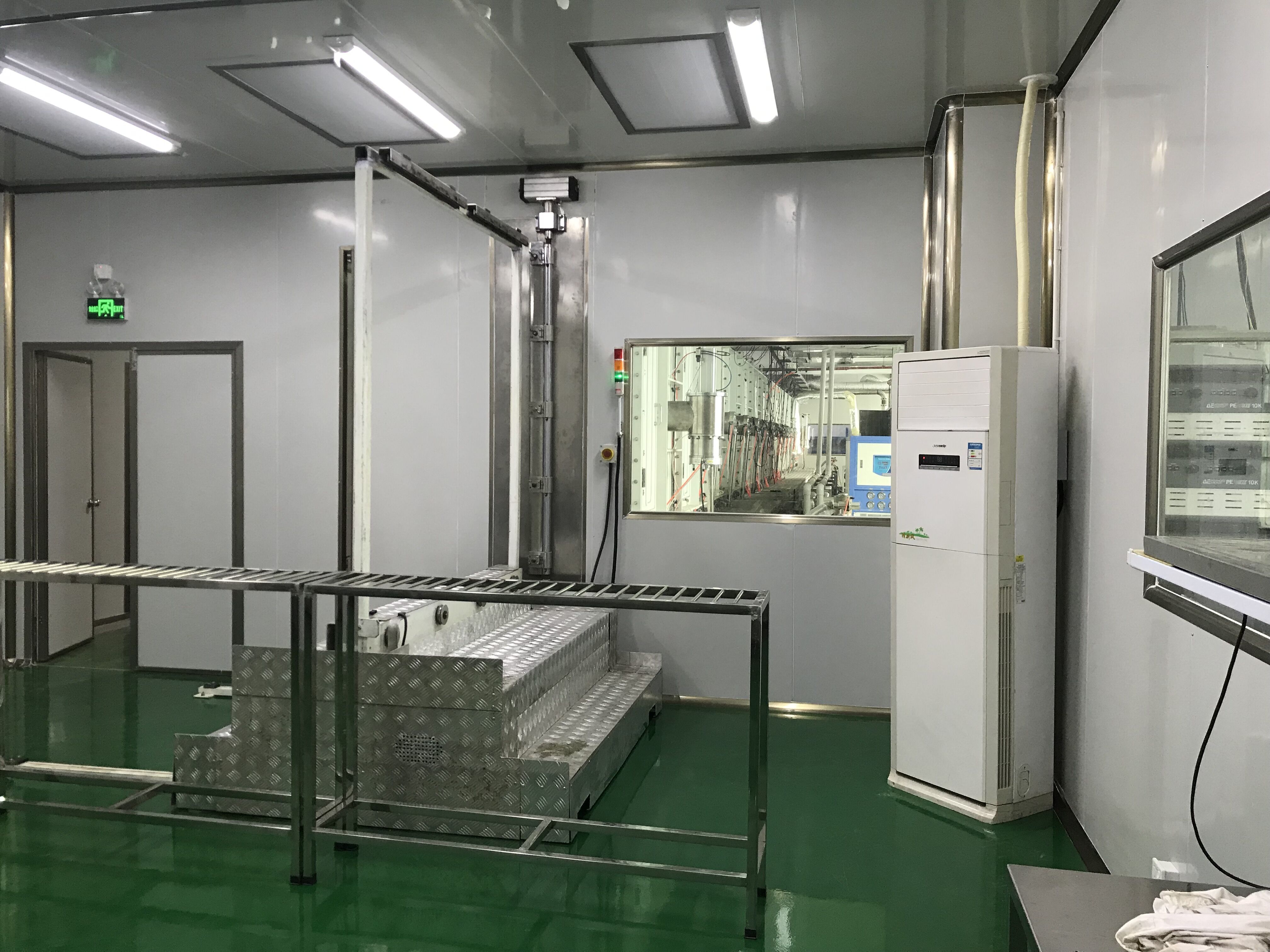

- The ITO glass inline sputtering system is capable to apply different coatings on substrates. We provide design and complete set of machines according to the customers’ requirements, we can also provide the technical support for recipes and TURNKEY project service.

Material of the vacuum chambers of Continuous ITO Glass Sputtering Line is SUS304, the interior wall is polished. And the exterior wall is sprayed beads after polishing.

- Transmission of vacuum chamber is done by the magnetic solenoid to ensure the stability of transmission. Speed for each section of the whole production line is driven by variable frequency motor, the speed is adjustable.

- Controlling system of Continuous ITO Glass Sputtering Line: Touched screen and PLC automatic control

- Application: glass panels of mobile phones, electronics, home appliances and displays

- 1. Vacuum chamber is made of stainless steel, vertical structure and the out wall connects with cooling water, inner wall with stainless steel block.

- 2. Vacuum system: Both of diffusion pump system and turbo molecular pump system are available.

- 3. Evaporation source: DC magnetron sputtering target, unbalanced magnetron sputtering target are respectively fixed on both sides of the vacuum chamber.

- 4. Workpiece drying system: The sputtering line adopts stainless tubular heater and vapor chamber to assure the heating homogeneity of the glass.

- 5. Air inflating system: mass-flow gas meter and automatic pressure controller.

- 6. Electrical control system: touch-screen and PLC automatic control to realize data display, operation and control by human-machine conversation system.

- 7. Water cooling system: vacuum cooling and cathode cooling system with water pressure protection switch and water flow switch.