- (1) The thickness of the coating can be controlled, according to the needs of people plating film, and the coating can be repeated, but also to break the limit of the prior art, to obtain a uniform film thickness on a large surface;

- (2) Film obtained by this technique with strong adhesion;

- (3) This technique can be prepared a special film material, according to their needs while sputtering hybrid film, compound film;

- (4) high purity film.

- Applicable materials: plastic, metal and glass

- Film layer types: titanium, aluminum, silver, chromium, titanium, stainless steel and other metals or alloy coatings

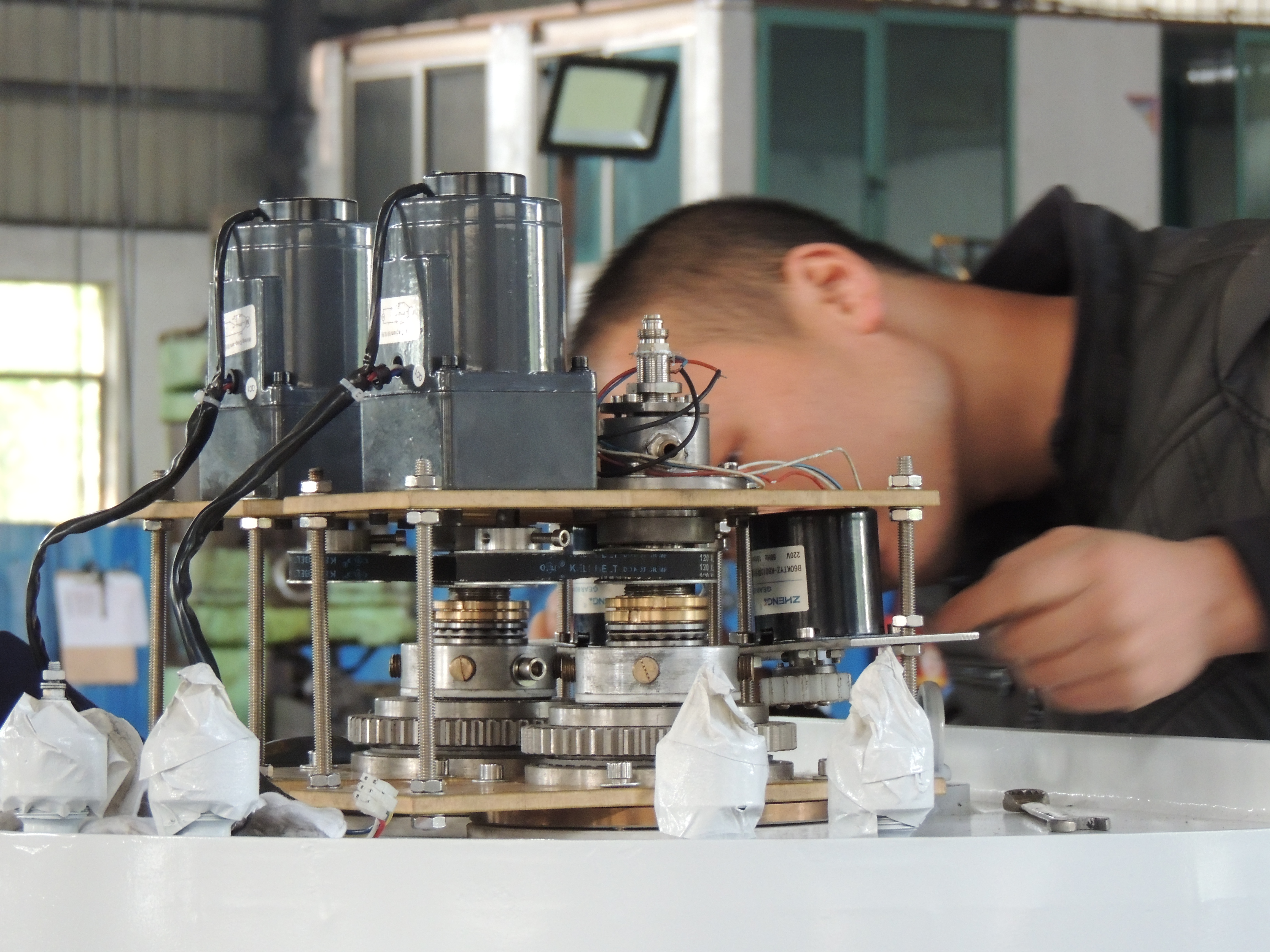

- Equipment size: According to customer requirements, you can design a single chamber, single -door, single –chamber double door, dual - chamber equipment

- Control system: PLC control system (automatic, manual optional)

- Power: DC power supply or intermediate frequency power supply

- Equipment color: available for customer customization

- Coating cycle: batch coating for 10-15 minutes

- Operator: 2-3 persons

- Each hour of power consumption: about 40kW

- Production materials: carbon steel or stainless steel

- Supporting engineering: compressed air, cooling water

- Occupy area: according to customer customization requirements

- We can also use the sputtering process to increase the characteristics, density, and uniformity of the membrane layer. Suitable for crystal glass products, crafts, plastic products, electronic products and other industries, have good development prospects. If there is a need for magnetic sputtering coating production lines, you are welcome to inquire.